Installing and setting up for the Ultima DACE Motor

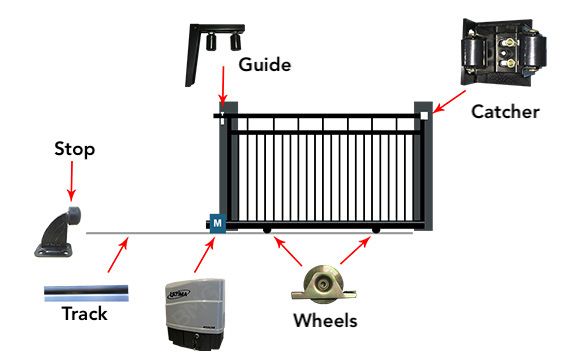

Sliding gate track

Gate wheels

Ensure your wheels are in good condition and that you can manually push your gate without any change in your push force.

It's not advised to use 3 wheels

Gate stop

A gate stop is required for the open position. This will prevent the gate from running off the track if the gate fails to stop.

The motor will learn from this stop.

Gate catcher

The gate catcher is required for the closed position of the gate. This will help prevent anyone from trying to lift your gate off the track as well as a fail safe for stopping.

The motor will learn from this stop catcher.

Gate guide

Gate check

Accessing the motor and removing the lid

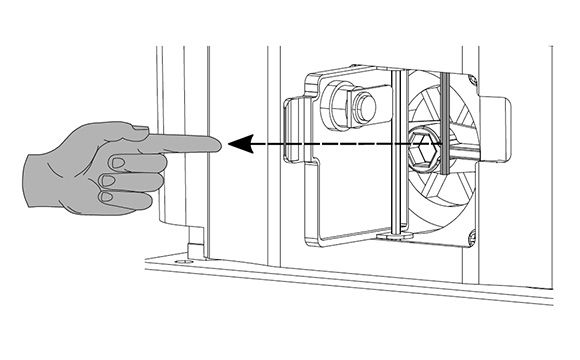

Placing the motor into manual override

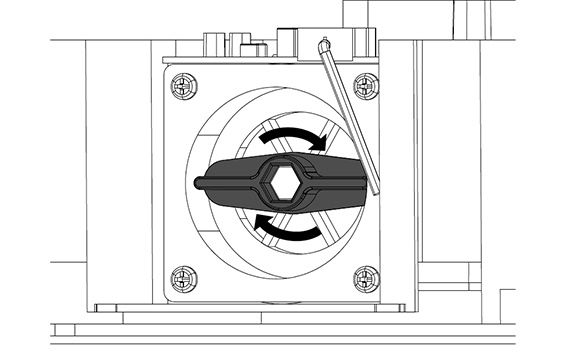

To check if the motor is already set to manual mode, try turning the cog clockwise. If the cog turns then you know it's already in manual mode and if it doesn't turn then follow the instructions below.

Open the 'manual release door' and rotate the thumbwheel clockwise up to 5 full revolutions which should release the cog and place the motor into manual mode. The thumbwheel should not be allowed to rotate too far.

To re-engage the motor when you have it setup on the gate, rotate the thumbwheel counter clockwise while pushing on the gate until you hear a click in the gearbox.

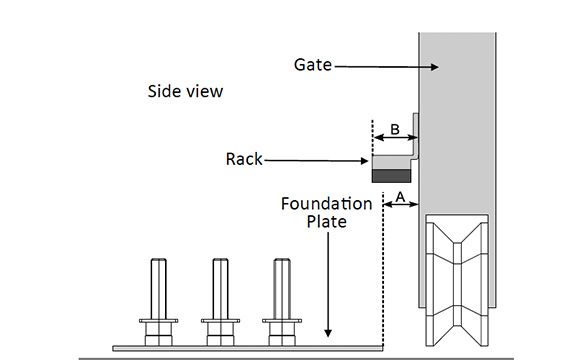

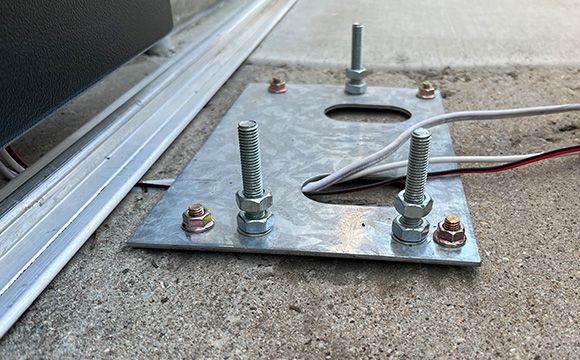

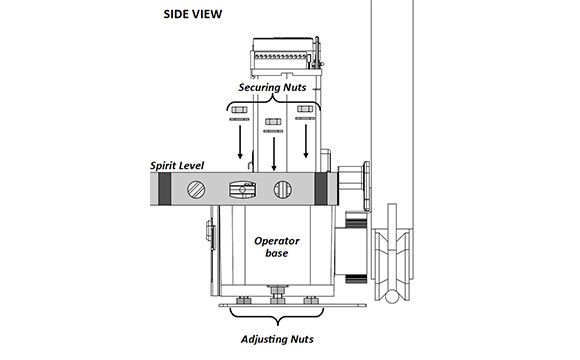

Anchoring the foundation plate

Secure the motor to the foundation plate

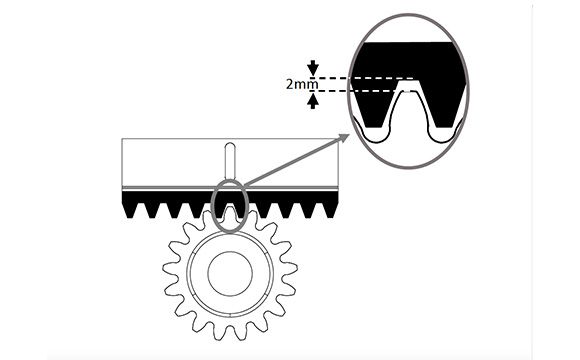

Mounting the rack on the gate

Placing oil in the gearbox - VERY IMPORTANT

The gearbox has been supplied with no oil. You will need to fill the gearbox with the oil provided before commissioning the motor. Failing to do this may damage the motor and void your warranty.

Only us SAE75W-90 oil to refill

Fill the gearbox with the oil provided as shown. The entire (70ml) must be emptied into the gearbox.

Mounting the marker magnet - EXTREMELY IMPORTANT

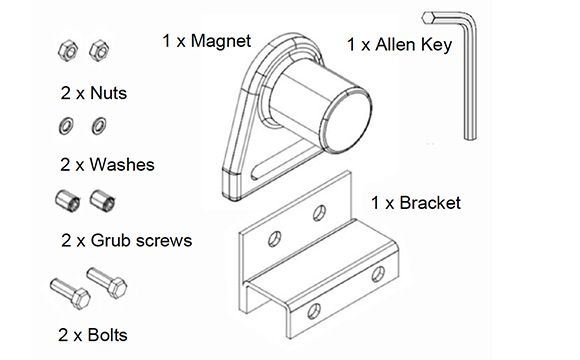

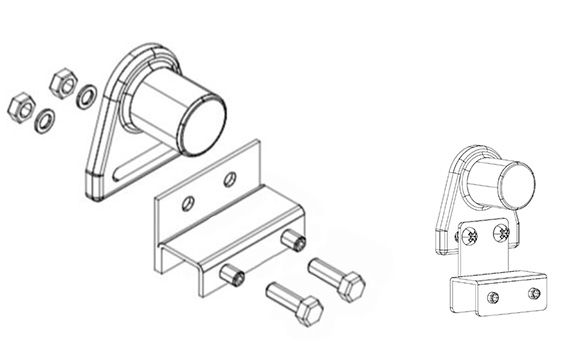

Asselmbling the magnet

Step 1. Install the grub screws with the allen key

Step 2. Install the 2 bolts

Step 3. Attach the magnet to the bolts

Step 4. Attach the washers

Step 5. Attach the nuts and tighten

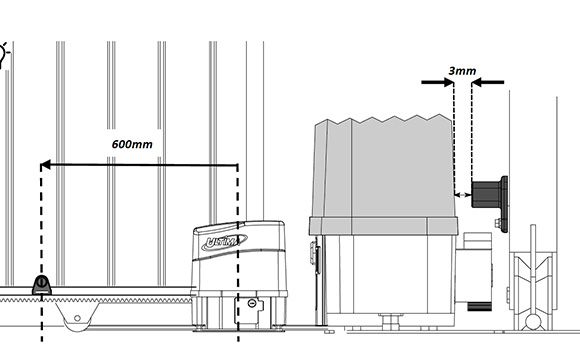

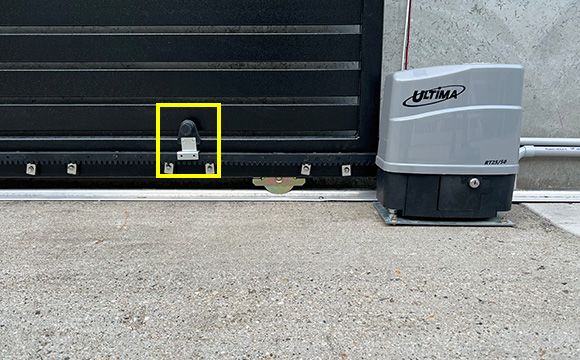

Mounting the magnet

Step 1. Push the gate to the fully closed position.

Step 2. Place the magnet on the rack, 600mm from the centre of the motor.

Step 3. Secure the magnet bracket to the gear rack and tighten grub screws.

Step 4. The space between the lid and the magnet must not exceed 3mm. If it does, place washers behind the magnet to reduce the space.

Do not invert the magnet. Only use the magnet supplied with the operator.

Wiring up and commissioning your motor

Once your gate and motor are setup correctly, you can then move onto wiring up your power option which will be either transformer or solar and connecting your 12v battery. You will find these details on page 18 of your user manual. We recommend commissioning your motor first before adding any other accessories and operating the gate a few times to make sure your setup is correct and the motor is operating as it should.