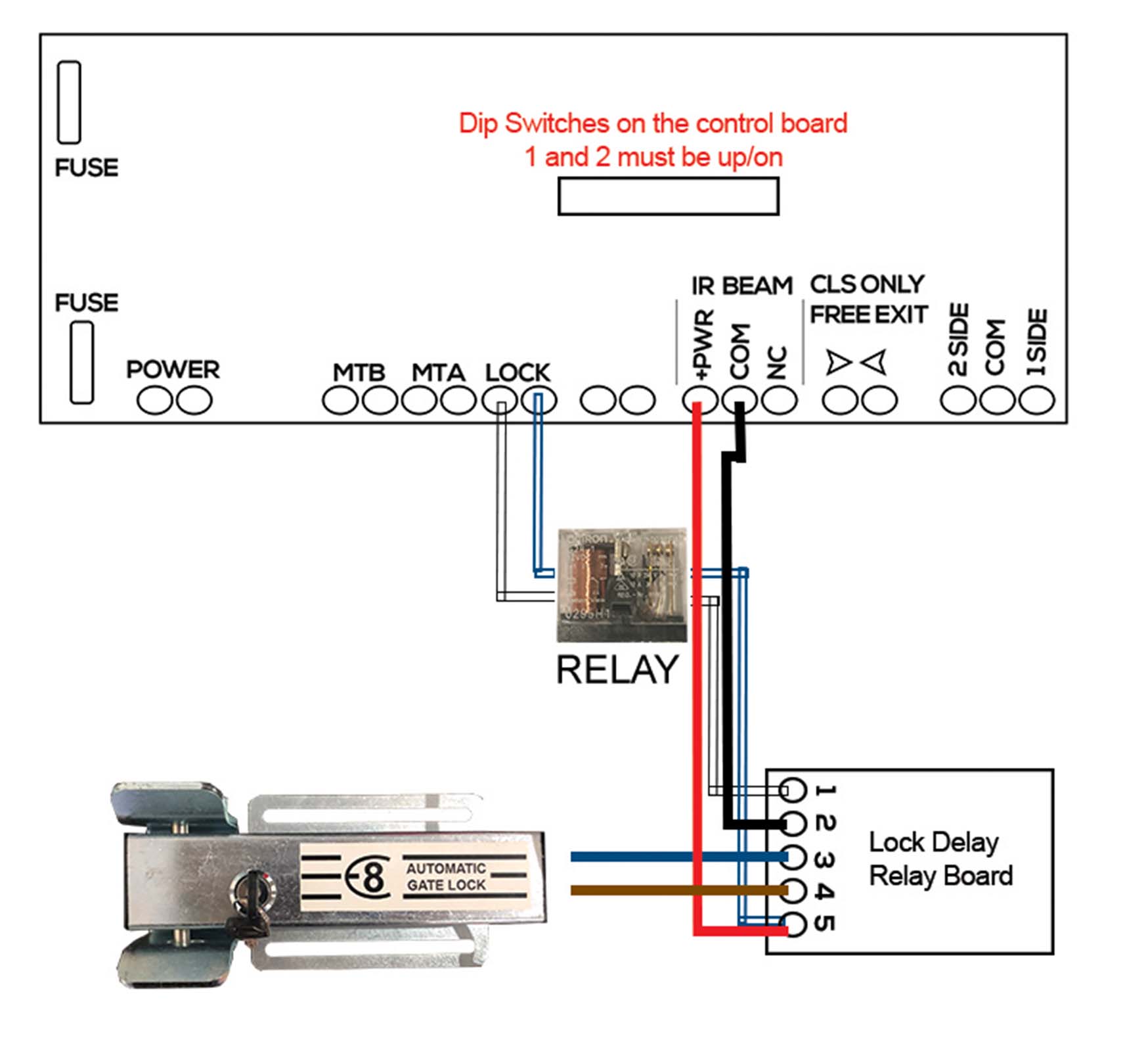

Wiring E8 EGA Gate Lock

E8 EGA Board - Gate Lock Installation

EGA Control Board Menu Settings

Once you have your gate lock connected you will need to make the following adjustments on your control board.

P8 = Opening/Closing Delay Time

This setting is for Dual Swing gates. You can adjust the opening/closing delay between the two motors. This is required if you have an electric gate lock connected to the control board or if you require Motor 2 to open first and Motor 1 to close first. You can set this from 0 seconds (open and close at the same time) up to 8 seconds. Factory setting is 2 seconds and is recommended even if a gate lock is not installed.

0 = No Delay

1 = 1 second

2 = 2 seconds (factory set)

3 = 3 seconds

4 = 4 seconds

5 = 5 seconds

6 = 6 seconds

7 = 7 seconds

8 = 8 seconds

1 = 1 second

2 = 2 seconds (factory set)

3 = 3 seconds

4 = 4 seconds

5 = 5 seconds

6 = 6 seconds

7 = 7 seconds

8 = 8 seconds

PA = Electric Lock Output Mode

This setting allows you to adjust the output to you optional electric gate lock. Factory setting is 0 which is set for NO GATE LOCK. If you install a gate lock, it is recommended you set PA to level 3 (3 seconds). This may need to be adjusted depending on your gate setup. If lock output is set to 1, the lock will activate first for 1 second before the gate starts, this is to allow time for the lock to activate.

0 = No output (factory set)

1 = 1 second

2 = 2 seconds

3 = 3 seconds

4 = 4 seconds

5 = 5 seconds

6 = 6 seconds

1 = 1 second

2 = 2 seconds

3 = 3 seconds

4 = 4 seconds

5 = 5 seconds

6 = 6 seconds

PC = Electric Lock Auxiliary Function

Factory setting Motor 2 will activate after 1 second to allow the gate lock to release. Setting PC to 1 will make Motor 2 reverse (close) for 0.5 seconds to help release pressure off the gate lock before allowing Motor 2 to activate.

0 = Open (factory set)

1 = Close reverse first

1 = Close reverse first

Read more: Wiring E8 EGA Gate Lock

- Hits: 8761